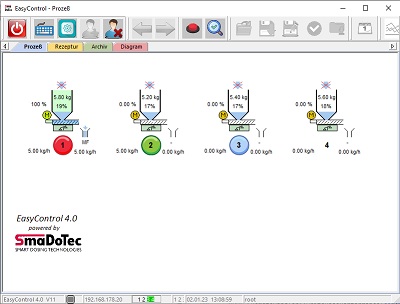

For the control and regulation of our gravimetric feeders we use our EasyControl 4.0 control software. The special feature of our self-developed software is the absolute focus on user-friendliness and flexibility with the highest accuracy requirements.

Whether via touch screen or remote computer in the local network or even via Internet, everything the modern PC world offers is available to you at the click of a mouse.

Thanks to Microsoft’s Windows 10 IoT-64 bit operating system, we always have our finger on the pulse when it comes to Internet security and software updates.

EasyControl is available as a master or slave configuration. Master means that the dosing is managed and controlled completely autonomously by the EasyControl 4.0. In the slave configuration, an external master (e.g. an extruder) takes over control of the dispensing process and communicates with the dispensing controller via an interface (e.g. ProfiNet) for this purpose.

The most important functions at a glance

EasyControl 4.0

- Latest, high-performance Beckhoff computer hardware based on Microsoft Windows 10 IoT 64-bit and Beckhoff TwinCat 3.x

- Simple touchscreen operation with recipe management

- Configurable internal and external interlocking

- Coupling of different gravimetric feeders with different weighing techniques

- vibrating string, e.g. pesa

- Strain gauges DMS, e.g. Soemer, Hottinger, Utilcell etc.

- Control of up to 32 dosing units

- Bus coupling to higher-level control systems via Siemens S7 Industrial Ethernet, Modbus, ProfiNet or ProfiBus.

- Connection to ERP and data acquisition systems

Available in the following languages

Flexibility, why XML ?

A major disadvantage of comparable dosing controls from other manufacturers is that a certain repertoire of interfaces for external communication is hard-coded, small adjustments are possible, but the customer is more or less presented with a fixed framework, which does not necessarily reflect his local conditions. The consequences are programming efforts, time-consuming tests on both sides and in the end a protocol that is used in this form perhaps only once and is hardly taken into account in further software adaptations / bug fixes.

This is where EasyControl 4.0 comes in, we adapt to your circumstances. Where which command and which value is read and which date is given to the outside, you can decide yourself. You benefit automatically from software adaptations / bug fixes without affecting the communication.

How is this possible ?

This is made possible by the fact that EasyControl 4.0 has a so-called generic remote handler that works independently of the selected protocol. The remote handler is “fed” via so-called XML configuration blocks, which are adapted to the local conditions via an editor.

We create the XML file accordingly for you according to your specifications. The special thing is, should your requirements change over time, then you either adapt the XML file yourself, or we do it for you. This can be done remotely or by mail, usually no 24h are necessary and your system is already working with the modification.

Configurable internal and external interlocking

We also set new standards in terms of interlocking and maximum flexibility. A major disadvantage of other dosing controls is the static interlocking, which can only be modified with programming knowledge or, if necessary, by rewiring. The classic case, one feeder may only start after another has been started before. Of course you can implement something like this on a logo or hardwire the releases. But what happens if the dosing units for another product are assembled differently and the dependencies change ? Reprogram the Logo ? Call the electrician and rewire the control cabinet ? At the next product change the same again from the beginning ?

Here, too, we take a different approach. We do without additional logo hardware and rewiring is a thing of the past. We solve the task with software. With our flexible XML construction kit you configure your system and the dependencies as the current situation requires. All this without programming or rewiring. Even more complicated logical conditions and dosing relationships can be formulated in the form of Boolean expressions.

But the XML logo handler does even more. The run monitoring can be parameterized and activated just as easily and all without programming knowledge.

Siemens Industrial Ethernet

If your system is configured as a slave and you operate an S7 controller as a master, then communication via Industrial Ethernet in combination with our XML modular system is particularly easy to implement. It does not matter whether your master is an S7-300, S7-400, an S7-1200 or an S7-1500.