We use two weighing technologies in our platform scales to calculate weight loss during gravimetric feeding. The Pesa string technology and the strain gauge principle.

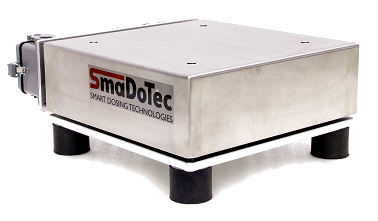

Our scales, enclosed in solid stainless steel housings, are available in four sizes, each with different nominal loads. The plug-in connections are located at the rear and are positioned at an optimum height with regard to gentle bending radii of the cable harness. Which weighing technology is used is usually product- or customer-specific, although externally the platform scales do not differ.

Optionally all scales are also available for ATEX zones, on request also with ATEX connector sets.

| Plattform scale | Width, Depth [mm] | Height [mm] | Type | Nominal load [kg] | Bus type |

|---|---|---|---|---|---|

| PS3-P30/75/150 | 300 | 150 | PESA | 30/75/150 | RS485 |

| PS3-SU50/75/120/200 | 300 | 150 | DMS | 50/75/120/200 | RS485 |

| PS3-SHRU50/75/120/200 | 300 | 150 | DMS-HR | 50/75/120/200 | RS485 |

| PS3-SL50/75/120/200 | 300 | 150 | DMS | 50/75/120/200 | EtherCAT |

| PS4-P30/75/150 | 400 | 150 | PESA | 30/75/150 | RS485 |

| PS4-SU50/75/120/200 | 400 | 150 | DMS | 50/75/120/200 | RS485 |

| PS4-SHRU50/75/120/200 | 400 | 150 | DMS-HR | 50/75/120/200 | RS485 |

| PS4-SL50/75/120/200 | 400 | 150 | DMS | 50/75/120/200 | EtherCAT |

| PS6-P300/600 | 600 | 150 | PESA | 300/600 | RS485 |

| PS6-SU300/600 | 600 | 150 | DMS | 300/600 | RS485 |

| PS6-SHRU300/600 | 600 | 150 | DMS-HR | 300/600 | RS485 |

| PS6-SL300/600 | 600 | 150 | DMS | 300/600 | EtherCAT |

| PS8-SU400/600/1000 | 800 | 150 | DMS | 400/600/1000 | RS485 |

| PS8-SHRU400/600/1000 | 800 | 150 | DMS-HR | 400/600/1000 | RS485 |

| PS8-SL400/600/1000 | 800 | 150 | DMS | 400/600/1000 | EtherCAT |

The Pesa strings technology

In Pesa string technology, the tension of the vibrating string is influenced by the introduced mass, which changes the vibration frequency of the string. The weight is calculated from the change in vibration frequency. ( Source PESA – Weighing Systems, PESA Waagen AG )

Strain gauge

A strain gauge is a sensor whose electrical resistance changes with the applied force. The change in resistance is accompanied by a change in the measuring voltage, which can be read out via a measuring amplifier and an analog-to-digital converter.